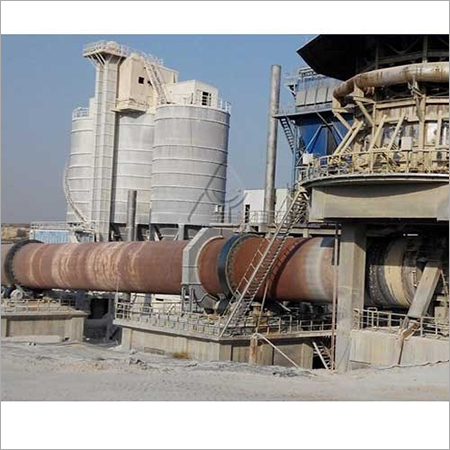

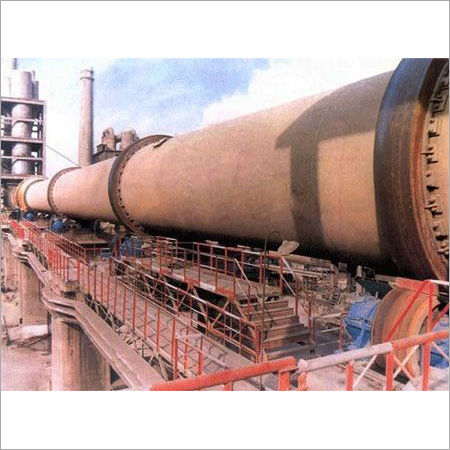

Kiln Engineering Consultancy Service

MOQ : 1 Unit

Kiln Engineering Consultancy Service Specification

- Analysis Methods

- Thermal Calculation, Stress Analysis, Process Optimization

- Service Mode

- Offline

- Consultancy Provided For

- Rotary and Vertical Kilns

- Service Type

- Kiln Engineering Consultancy

- Usage

- Industrial Kiln Design and Operation

- Client Training Offered

- Kiln Operation and Maintenance Workshops

- Project Duration

- Customizable as per client needs

- Location

- On-site

- Deliverables

- Project Reports, Process Blueprints, Efficiency Assessment

- Safety Standards Followed

- International Kiln Safety Compliance

- Post-service Assistance

- Remote and On-site Follow-up

- Expertise Level

- Senior Engineering Consultants

- Availability

- Pan India and International

- Support

- Technical Documentation and On-field Guidance

- Industry

- Cement, Lime, Refractory, Metallurgy

Kiln Engineering Consultancy Service Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units, Unit Per Week

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Kiln Engineering Consultancy Service

We offers Specialized Maintenance Services for Kiln Alignment (Hot and Cold), Diagnostic Maintenance, Kiln and components Erection, Tyre-Roller Grinding, etc covering several industries namely Cement, DRI, Fertilizer, Chemical, Carbon, Steel, etc.

Senior Engineering Expertise for Enhanced Kiln Performance

Backed by a team of seasoned consultants, we specialize in delivering robust engineering solutions for rotary and vertical kilns. Our approach integrates rigorous analysis methods such as thermal calculation and stress assessment, ensuring optimized kiln operation for sectors including cement, lime, and metallurgy. Rely on our depth of knowledge for long-term efficiency and safety.

Comprehensive Project Support from Start to Finish

Our consultancy framework is designed for flexibility, offering fully customizable project durations and a blend of remote and on-site assistance. From the initial assessment to process blueprints and final project reports, clients receive meticulous technical documentation, ongoing guidance, and post-service support, guaranteeing results that meet international safety standards.

Empowering Clients with Training and Technical Guidance

Beyond engineering solutions, we focus on empowering client teams through targeted workshops covering kiln operation and maintenance. By combining hands-on guidance with technical documentation, we ensure seamless knowledge transfer and skill development, supporting sustained operational excellence.

FAQs of Kiln Engineering Consultancy Service:

Q: How does the Kiln Engineering Consultancy Service ensure project success for industrial kilns?

A: Success is achieved through senior engineering expertise, detailed technical documentation, and rigorous analysis methods, including thermal calculation and stress analysis. Customizable project durations and on-field guidance ensure every clients specific needs are addressed, resulting in optimized operations and efficiency.Q: What types of kilns and industries are covered by this consultancy?

A: We provide consultancy for both rotary and vertical kilns, serving industries such as cement, lime, refractory, and metallurgy. Our services are designed to address the unique requirements and challenges found within these sectors.Q: When and where can clients access your engineering services?

A: Clients can access our consultancy services on-site at any industrial location across India and internationally. Service scheduling is flexible and tailored to project needs, ensuring timely support for various operational timelines.Q: What processes are analyzed to improve kiln performance and safety?

A: Processes analyzed include detailed thermal calculations, stress analysis, process optimization, and safety compliance assessments. Our senior consultants use these methods to enhance kiln efficiency while ensuring adherence to international safety standards.Q: How is client training integrated into the consultancy offering?

A: Client training is provided through kiln operation and maintenance workshops, conducted on-site for hands-on learning. Technical documentation supports these sessions, equipping teams with practical knowledge for long-term operational reliability.Q: What deliverables can clients expect at the end of a project?

A: Clients receive comprehensive project reports, detailed process blueprints, efficiency assessments, and documentation demonstrating adherence to international safety standards. These deliverables are designed to support ongoing improvements and regulatory compliance.Q: What benefits does post-service assistance provide?

A: Post-service assistance includes both remote and on-site follow-up, ensuring continued support for troubleshooting, operational optimization, and further training as needed. This helps maintain kiln performance and resolves any emerging challenges promptly.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Kiln Services Category

"We also offered Our Services in Indian Subcontinent, East/Middle Africa, North Africa, South/West Africa, East Asia, South East Asia & Middle East Countries.

Send Inquiry

Send Inquiry