Kiln Girth Gear Alignment Services

MOQ : 1 Unit

Kiln Girth Gear Alignment Services Specification

- Usage/Application

- Industrial

- Inspection Reports Provided

- Yes, with precision measurement data

- Service Duration

- As per project requirement

- Emergency Service Availability

- Yes, on request

- Alignment Accuracy

- Up to 0.05 mm

- Maximum Gear Diameter

- Up to 10 meters

- Service Type

- Kiln Girth Gear Alignment Services

- Technician Expertise

- Experienced engineers with advanced alignment techniques

- Alignment Method

- Laser and Manual Measurement

- Gear Material Compatibility

- MS, Alloy Steel, Carbon Steel

- Service Location

- Pan India

- Equipment Serviced

- Rotary Kilns, Ball Mills, Dryers

- Service Mode

- Offline

Kiln Girth Gear Alignment Services Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Mumbai

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 15 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Western Europe, Middle East, Central America, Eastern Europe, South America, Asia, North America, Australia, Africa

- Main Domestic Market

- All India

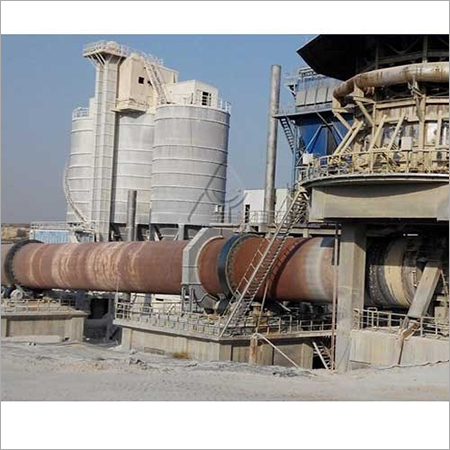

About Kiln Girth Gear Alignment Services

Hot Kiln Alignment Service that we offer are reputed for zero error and close tolerances. We offer specialized Kiln Alignment solutions using the latest technology and tools. Our team is proficient and experienced in carrying out Kiln Alignment jobs of any scale, small or large. Our ability to locate the recurring problems and eliminating them enables us to offer Hot Kiln Alignment Service.

Precision Alignment for Enhanced Equipment Performance

Accurate girth gear alignment is critical to reducing wear, preventing downtime, and ensuring the efficient operation of rotary kilns, ball mills, and dryers. Our alignment techniqueslaser and manualprovide high precision, resulting in extended equipment life, lowered maintenance costs, and improved operational reliability. Comprehensive inspection reports are issued, helping you maintain performance records and plan future maintenance.

Nationwide Service Delivery and Expert Technicians

Our alignment services cover pan-India locations and are executed by experienced engineers skilled in advanced alignment practices. Whether responding to scheduled maintenance or urgent situations, our team ensures all work is conducted efficiently and to the highest standards. We guarantee accurate, consistent alignment performance for diverse industrial applications, supporting your operations wherever you are.

FAQs of Kiln Girth Gear Alignment Services:

Q: How is the kiln girth gear alignment process performed?

A: We utilize both advanced laser technology and precise manual measurement tools to align girth gears. These methods ensure high accuracy, minimize mechanical stress, and are suitable for MS, alloy steel, and carbon steel gears.Q: What equipment can be serviced through this alignment service?

A: Our service supports rotary kilns, ball mills, and dryers, handling girth gears up to 10 meters in diameter across these industrial machines.Q: When is it necessary to request emergency alignment services?

A: Emergency services should be considered when you experience unexpected misalignment, abnormal noise, or vibration in your kiln, mill, or dryer. Prompt alignment prevents further damage and unplanned downtime.Q: Where are these alignment services available?

A: We provide onsite alignment services across the entire Pan India region, deploying experienced technicians directly to your industrial location.Q: What types of gears are compatible with this service?

A: Our alignment solutions are compatible with MS (mild steel), alloy steel, and carbon steel girth gears, ensuring versatility for various industrial requirements.Q: What benefits does precision girth gear alignment offer?

A: Accurate alignment reduces excessive wear, improves equipment efficiency, and extends service life, ultimately lowering maintenance costs and increasing operational uptime.Q: Will I receive a report after the alignment process?

A: Yes, upon completion, you will be furnished with a detailed inspection report, including precision measurement data to support ongoing maintenance and reliability planning.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Kiln Services Category

"We also offered Our Services in Indian Subcontinent, East/Middle Africa, North Africa, South/West Africa, East Asia, South East Asia & Middle East Countries.

Send Inquiry

Send Inquiry