Hot Kiln Alignments Services

Hot Kiln Alignments Services Specification

- Inspection Method

- Thermal camera, electronic sensors, on-site assessment

- Service Type

- Hot Kiln Alignments Services

- Technology Used

- Latest laser and electronic measurement tools

- Service Coverage

- Available nationwide and internationally

- Equipment Compatibility

- Suitable for all rotary kiln makes and models

- Lead Time

- Can be scheduled within 7-14 days

- Reporting

- Detailed alignment report provided

- Downtime

- Minimizes operational downtime

- Usage

- Alignment of rotary kilns and large rotating equipment

- Safety Standards

- ISO and plant safety regulations compliant

- Service Mode

- On-site

- Benefits

- Improved kiln performance, extended life, reduced maintenance costs

- Accuracy

- High precision alignment

- Application

- Cement plants, mineral processing, and rotary kiln maintenance

- Post-Service Support

- Follow-up consultation and guidance provided

- Service Offered By

- Experienced technical team

Hot Kiln Alignments Services Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1 Unit Unit Per Day

- Delivery Time

- 10 - 15 Days

- Main Domestic Market

- All India

About Hot Kiln Alignments Services

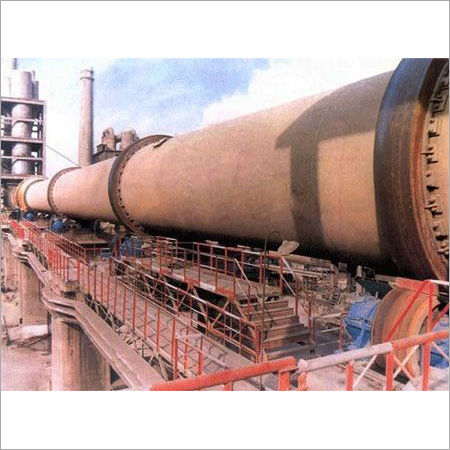

Being a leading organization in this entity, we established ourselves as a top-notch service provider of Kiln Alignment Services. We have a team of expert mechanical engineers who have hand-on experience on over 100 slow speed rotary machines for the alignment and trouble shoot of recurring mechanical problems. By utilizing advanced techniques and quality assured components, we are offering this service as per the varied need of clients. Moreover, our clients can take advantage of this HotKiln Alignment Services at affordable prices.Key Features:

- Ensure detailed and fully-integrated strategy

- Rendered with hassle free managements

- Cherished due to its hassle-free management and cost-effectiveness

Kiln shell ovality is an important parameter to assess kiln health and the monitoring become mandatory upon recurring refractory problem. Ovality, is defined as difference of shell diameter in horizontal and vertical axis. The difference arises because of flexing in kiln shell during operation, thermal, material loading, etc attributed for the difference.

The shell flexing is governed by following factors:

Beam strength of tyre

- Kiln shell thickness

- Kiln shell and tyre temperatures

- Kiln shell misalignment

- Air gap between tyre ID & chairpad OD.

- Thermal and material loading

- High run-out of kiln shell close to support stations, etc

Variation in any of above factors influence shell ovality and has a detrimental effect upon the exceedance. Higher ovality has influence over refractory failure under / close by tyre section, undue stress on kiln shell and tyre section. If higher stresses are allowed for extended period, premature failure of refractory / mechanical element may results.

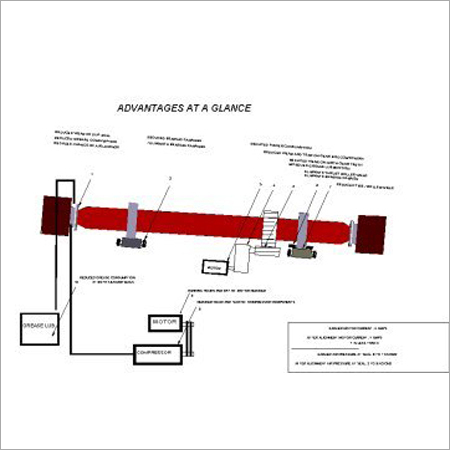

The measurement (services) is being carried out using high resolution beam, by directly mounting the sensor on shell during normal operation. The sensor measure and record the shell flexing using strain gauge (instead of dial gauge), during operation for the analysis. Manual transfer error is eliminated by continuously transfer of collected data from the sensor directly to data logger (laptop) during the operation using blue tooth data transfer technology.

Comprehensive On-Site Assessments

Our hot kiln alignment services are carried out directly at your site, ensuring accurate assessments under real operational conditions. Utilizing the latest electronic measurement tools and thermal cameras, our experienced technical team provides precise alignment readings for all rotary kiln types, regardless of manufacturer.

Detailed Reporting and Expert Consultation

After every alignment service, clients receive a thorough and detailed alignment report outlining the measurements, adjustments made, and recommendations for ongoing performance. Our follow-up consultation ensures you have expert support to interpret results and implement actionable improvements.

Nationwide and International Coverage

We offer our hot kiln alignment services across India and internationally, ensuring clients in diverse locations have seamless access to precision alignment and maintenance expertise. Our team is ready to schedule your project within 714 days, minimizing your equipments downtime.

FAQs of Hot Kiln Alignments Services:

Q: How is hot kiln alignment performed during operation without stopping the kiln?

A: Hot kiln alignment is conducted while the kiln remains operational using advanced thermal cameras, electronic sensors, and laser-based measurement tools. This process allows for real-time data collection, ensuring high accuracy while minimizing any operational downtime.Q: What benefits can I expect from regular hot kiln alignment services?

A: Regular hot kiln alignment reduces maintenance costs, prevents unexpected failures, and extends the lifespan of rotary kilns. Proper alignment also enhances kiln efficiency, leading to improved performance and greater energy savings.Q: When can I schedule a hot kiln alignment service, and how soon can it be performed?

A: Our services can typically be scheduled within 7 to 14 days, depending on your location and specific requirements. Early scheduling ensures timely alignment and minimal disturbance to your production schedule.Q: Where are hot kiln alignment services available?

A: We provide hot kiln alignment services nationwide across India and internationally, offering support wherever your cement plant, mineral processing facility, or rotary kiln operations are located.Q: What is included in the hot kiln alignment service process?

A: The service includes an on-site assessment using laser, thermal, and electronic measurement tools, alignment adjustments as needed, a detailed alignment report, and a follow-up consultation to review findings and recommendations.Q: Who conducts the hot kiln alignment, and what standards are followed?

A: An experienced technical team, compliant with ISO and specific plant safety regulations, performs the alignment. Our specialists use industry-leading methods to ensure dependable and precise outcomes for every project.Q: What types of rotary kilns and large rotating equipment are compatible with these alignment services?

A: Our alignment services are suitable for all makes and models of rotary kilns and large rotating machinery typically used in cement manufacturing, mineral processing, and related industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry