Hot Kiln Alignments Services

Product Details:

Hot Kiln Alignments Services Price And Quantity

- 1 Unit

- 500.00 - 1000.00 INR

Hot Kiln Alignments Services Trade Information

- Cash on Delivery (COD) Cash in Advance (CID) Cash Advance (CA)

- 1 Unit Unit Per Day

- 10 - 15 Days

- All India

Product Description

Hot Kiln Alignment

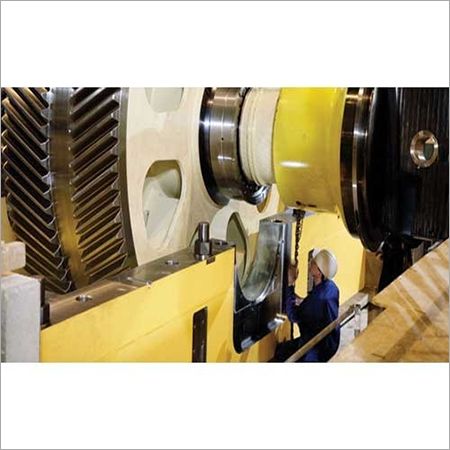

Being a leading organization in this entity, we established ourselves as a top-notch service provider of Kiln Alignment Services. We have a team of expert mechanical engineers who have hand-on experience on over 100 slow speed rotary machines for the alignment and trouble shoot of recurring mechanical problems. By utilizing advanced techniques and quality assured components, we are offering this service as per the varied need of clients. Moreover, our clients can take advantage of this Hot Kiln Alignment Services at affordable prices.

Key Features:

- Ensure detailed and fully-integrated strategy

- Rendered with hassle free managements

- Cherished due to its hassle-free management and cost-effectiveness

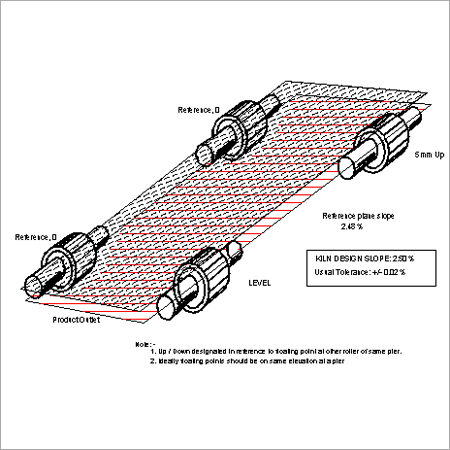

Kiln shell ovality is an important parameter to assess kiln health and the monitoring become mandatory upon recurring refractory problem. Ovality, is defined as difference of shell diameter in horizontal and vertical axis. The difference arises because of flexing in kiln shell during operation, thermal, material loading, etc attributed for the difference.

The shell flexing is governed by following factors:

Beam strength of tyre

- Kiln shell thickness

- Kiln shell and tyre temperatures

- Kiln shell misalignment

- Air gap between tyre ID & chairpad OD.

- Thermal and material loading

- High run-out of kiln shell close to support stations, etc

Variation in any of above factors influence shell ovality and has a detrimental effect upon the exceedance. Higher ovality has influence over refractory failure under / close by tyre section, undue stress on kiln shell and tyre section. If higher stresses are allowed for extended period, premature failure of refractory / mechanical element may results.

The measurement (services) is being carried out using high resolution beam, by directly mounting the sensor on shell during normal operation. The sensor measure and record the shell flexing using strain gauge (instead of dial gauge), during operation for the analysis. Manual transfer error is eliminated by continuously transfer of collected data from the sensor directly to data logger (laptop) during the operation using blue tooth data transfer technology.